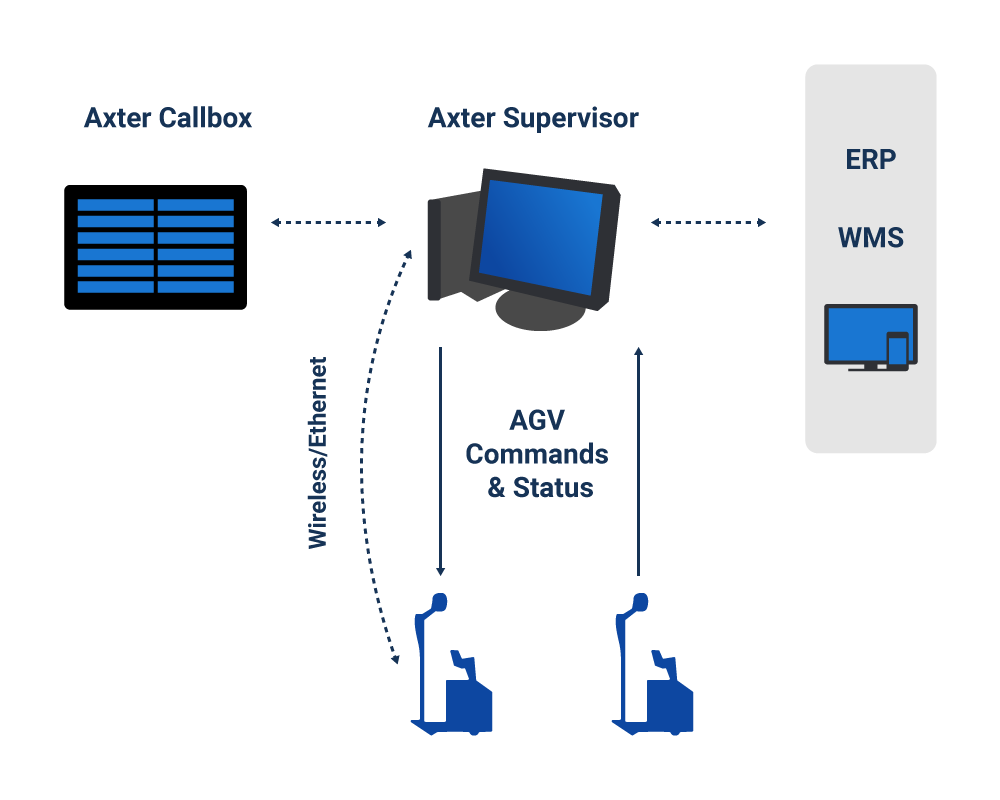

To make use of our AGV in a system Axter has developed a Supervisor or AGV Control System. It is an intelligent and easily integrated system software solution that enables user to get the maximum capacity from an installation of AGV. Our Supervisor’s main task is to control the AGVs’ traffic flow.

It is a simple computer that manages the AGV installation using a software developed by Axter. It is important to note that this AGV control system is not necessary even if the installation has more than 1 AGV.

Axter’s AGV control system drives better tracking and control of products. The system always knows where the products are located in your facility.

Our AGVs save on real time all their actions. They can provide historical and performance usage data and most importantly they can communicate with each other at any time.

When used in an installation, the standard version of our supervisor has the following functionalities:

- Receives and manage all tasks requested by the operators, machines and other systems such as ERP systems.

- Allocates and optimise automatically missions of AGVs based on priorities, localisation and availabilities of the AGVs.

- Traces the completions of the tasks requested

- Provides KPIs and historical data to that you can analyse and optimise constantly your

operations (e.g. usage rate, time analysis of each mission etc.) - Assists with remote maintenance of the installation

The Supervisor can also manage missions requested by product which helps the client to manage product traceability and product localisation in real-time